Wire mesh infill panels are available in the following specifications:

- carbon steel that is e-coated and powder coated

- powder coated aluminum

- stainless steel that is hem polished to you specification

Steel Wire Mesh Infill Panels

Our welded wire mesh infill panels are constructed from .120" diameter steel wire and every second wire is welded within the steel hem. Our hems are constructed from 11-gauge steel. To ensure that all water is evacuated from the system, the bottom hem is left completely open.

The load carrying strength of wire mesh infill panels cannot be calculated, therefore, we test the complete panel design on our testing rig to ensure it passes all appropriate building codes.

For outdoor use, our wire mesh infill panels are electro-coated and also powder coated to our standard color or to architect’s specifications.

Standard Selection

- 2” x 2” Square

Options

- 4" x 4" Square

- 1" x 1" Square

Rectangular Wire Mesh (various patterns)

- 2" x 1" Rectangular

- 1" x 3" Rectangular

- 2" x 4" Rectangular

Aluminum Woven Wire Mesh Infill Panels for Corrosive Environments

We can make aluminum wire mesh panels, which are great for highly corrosive environments, such along the coastlines. Aluminum wire mesh must be a larger gauge than steel to meet the 50 lb. on 1 sq. ft. loading requirement. Panels cannot be anodized, since the weld marks at the corners have a different shade post anodizing than the rest of the panel and U channel. We specify .250" diameter wire with 11 gauge hems In order to meet the loading requirements.

Since aluminum is often required in Florida, it is often also specified with AAMA 2605 coatings, which are great at retaining gloss and color. Hollaender can provide Kynar coatings that meet these specifications.

In settings that do not have “high sun exposure” applications, AAMA 2604, powder coat is generally satisfactory.

Stainless Steel Infill Panels

Stainless steel infill panels are available in 304 and 316 SS. Since 316 is extremely expensive, we recommend 304 SS as an alternative. The panel construction is similar to carbon steel with .120" OD mesh, 11 gauge hems with every second wire welded to the hem.

The major difference is in coating where stainless steel hems are polished to the desired specification, with our standard recommendation being #4 satin polish. Brighter finishes are also available.

Interna-Light™ Illuminated Railing Product Data

Interna-Light™ Illuminated Railing Product Data

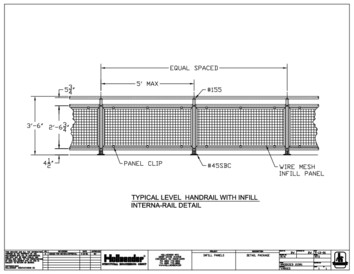

Interna-Rail® Railing System with Metal Infill Panels Product Data

Interna-Rail® Railing System with Metal Infill Panels Product Data

Speed-Rail® Quik Connect™ Product Data

Speed-Rail® Quik Connect™ Product Data

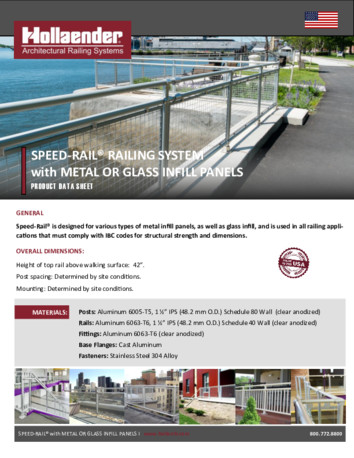

Speed‐Rail® Railing System with Metal or Glass Infill Panels Product Data

Speed‐Rail® Railing System with Metal or Glass Infill Panels Product Data

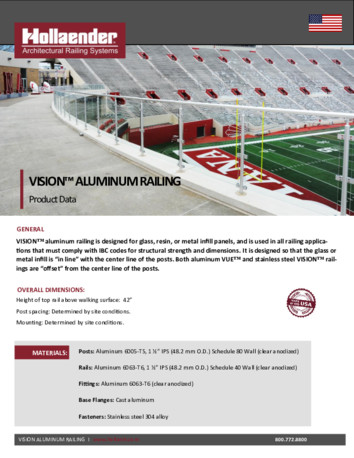

VISION™ Aluminum Product Data Sheet

VISION™ Aluminum Product Data Sheet

VISION™ Stainless Steel Railing Product Data

VISION™ Stainless Steel Railing Product Data

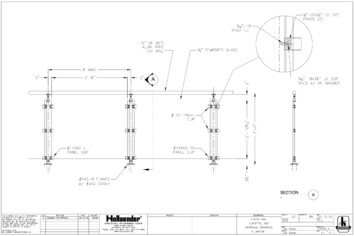

Interna-Rail® 2-Line with Wire Mesh

Interna-Rail® 2-Line with Wire Mesh

Interna-Rail® 3-Line with Wire Mesh

Interna-Rail® 3-Line with Wire Mesh

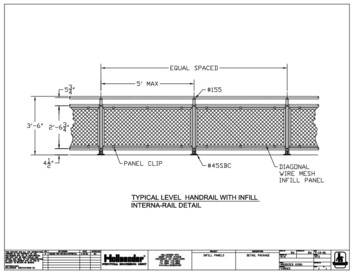

Interna-Rail® with Diagonal Wire Mesh Infill Panels

Interna-Rail® with Diagonal Wire Mesh Infill Panels

Interna-Rail® with Metal Infill Panels BIM

Interna-Rail® with Metal Infill Panels BIM

Interna-Rail® with Square Wire Mesh Infill Panels

Interna-Rail® with Square Wire Mesh Infill Panels

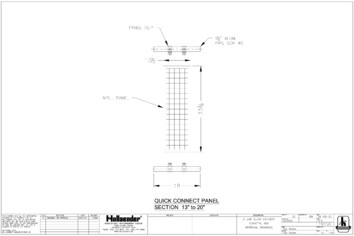

QC 13-20” Wire Mesh Infill Assembly

QC 13-20” Wire Mesh Infill Assembly

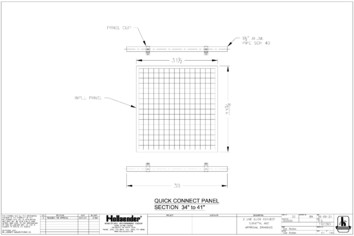

QC 34-41” Wire Mesh Infill Assembly

QC 34-41” Wire Mesh Infill Assembly

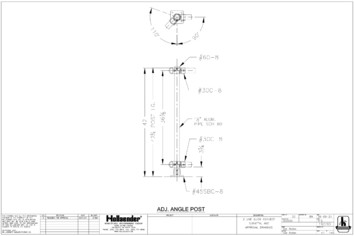

QC Adj. Angle Post Assembly

QC Adj. Angle Post Assembly

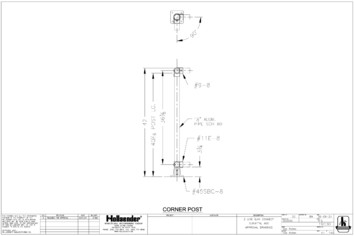

QC Corner 90 Deg Post Assembly

QC Corner 90 Deg Post Assembly

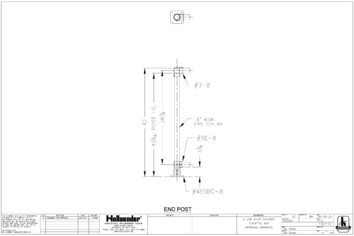

QC End Post Assembly

QC End Post Assembly

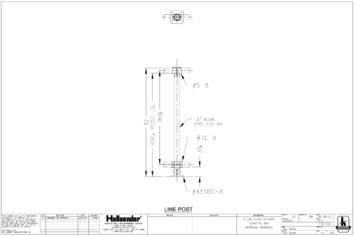

QC Line Post Assembly

QC Line Post Assembly

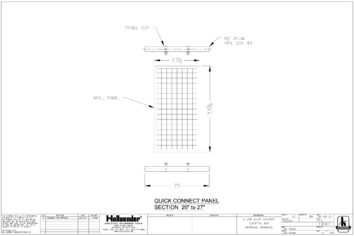

QC™ 20-27” Wire Mesh Infill Assembly

QC™ 20-27” Wire Mesh Infill Assembly

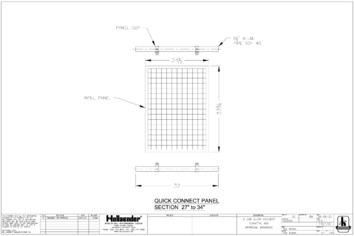

QC™ 27-34” Wire Mesh Infill Assembly

QC™ 27-34” Wire Mesh Infill Assembly

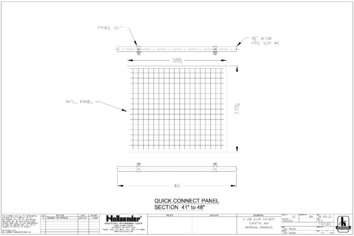

QC™ 41-48” Wire Mesh Infill Assembly

QC™ 41-48” Wire Mesh Infill Assembly

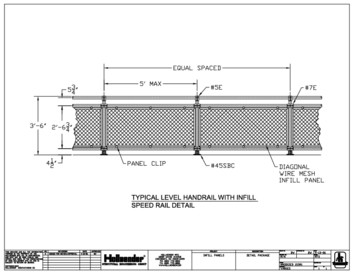

Speed-Rail® with Diagonal Wire Mesh Infill Panels

Speed-Rail® with Diagonal Wire Mesh Infill Panels

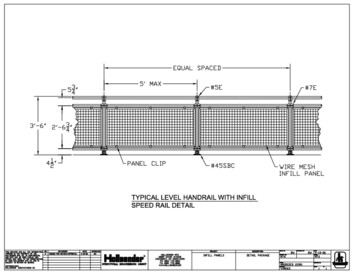

Speed-Rail® with Square Wire Mesh Infill Panels

Speed-Rail® with Square Wire Mesh Infill Panels

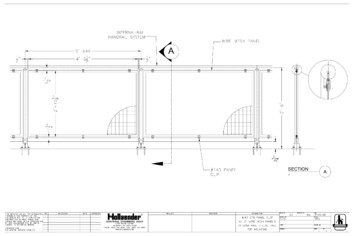

VISION™ Aluminum Railing Drawing

VISION™ Aluminum Railing Drawing